About Us

Welcome to SUNARROW CITI THAILAND

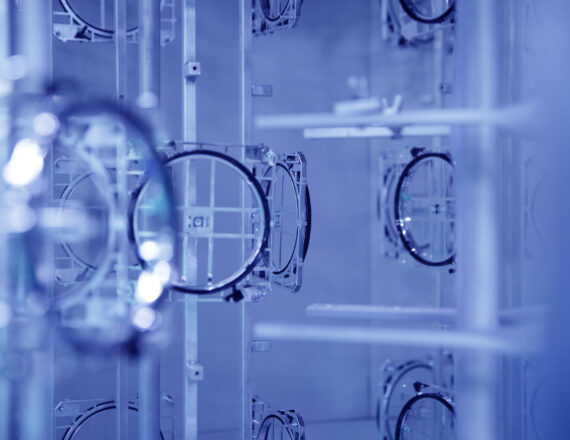

บริษัท SUNARROW CITI เราคือบริษัทชั้นนำด้านการให้บริการผลิตสินค้า OEM ให้กับบริษัทอุตสาหกรรมชั้นนำต่างๆบริษัท SUNARROW ได้ก่อตั้งขึ้นเมื่อปี ค.ศ. 1959 ณ กรุงโตเกี่ยว ประเทศญี่ปุ่น ซึ่งได้ดำเนินธุรกิจ ผลิตชิ้นส่วนอุปกรณ์ปุ่มกดมือถือ ให้กับ แบรนด์มือถือชั้นนำของโลกอย่าง Nokia และต่อมา บริษัท SUNARROW ได้เพิ่มกำลังการผลิต ขยายสาขาไปยังภูมิภาคเอเชีย และเพิ่มไลน์การผลิตสินค้าที่หลากหลายมากขึ้น

ได้แก่ อุปกรณ์อิเล็กทรอนิกส์ อุปกรณ์ยานยนต์ อุปกรณ์ อุปโภคบริโภค และอุปกรณ์ทางการแพทย์ ปัจจุบัน เรามีโรงงานการผลิต ทั่วภูมิภาคเอเชีย และหนึ่งในนั้นก็คือ

บริษัท SUNARROW CITI จำกัด ประเทศไทย ตั้งอยู่ที่ อำเภอหนองแค จังหวัดสระบุรี มีพื้นที่มากกว่า 20,000 ตารางเมตร ประกอบไปด้วย 4 โรงงานการผลิต

จำนวนพนักงาน เรามีพนักงานที่มีความชำนาญในการผลิต การออกแบบ การตรวจสอบคุณภาพสินค้า และพร้อมร่วมพัฒนาสินค้าไปกับลูกค้า กว่า 400 คน

ซึ่งสามารถรองกรับการผลิตที่เพิ่มมากขึ้น

รางวัลและมาตรฐานโรงงาน เราได้รับการรับรองมาตรฐาน

ISO9001 มาตรฐานระบบบริหารงานที่ได้คุณภาพตามมาตรฐานสากล

ISO14001 มาตรฐานระบบการจัดการสิ่งแวดล้อม ในโรงงานการผลิต

IATF16949 มาตรฐานระบบการบริหารจัดการคุณภาพสำหรับอุตสาหกรรมยานยนต์

ISO13485 มาตรฐานระบบการจัดการคุณภาพอุปกรณ์ทางการแพทย์

ทำให้ลูกค้ามั่นใจได้ว่าสินค้าของเราผลิตภายใต้การควบคุมตามมาตรฐานสากล

Numbers

ข้อมูลบริษัท

จำนวนพนักงาน

รางวัลและมาตรฐานโรงงาน ISO

จำนวนลูกค้า

ประสบการณ์ กว่า 30 ปี

วิสัยทัศน์

ปรัชญาองค์กร

Services

บริการของเรา SUNARROW SERVICES

เรารับผลิตสินค้า OEM Automotive

เรารับผลิตสินค้า OEM สำหรับกลุ่มผลิตภัณฑ์ Automotive อทิเช่น Keyless , Car window switch , Engine start ,หน้าจอเครื่องเสียงในรถยนต์

เรารับผลิตสินค้า OEM Medical

เรารับผลิตสินค้า OEM สำหรับกลุ่มผลิตภัณฑ์ Medical อทิเช่น เครื่องวัดระดับน้ำตาลในเลือด

เรารับผลิตสินค้า OEM Electronic

เรารับผลิตสินค้า OEM สำหรับกลุ่มผลิตภัณฑ์ Electronic อทิเช่น หูฟัง ( headphone ) , TV panel , Talking Dic ( Casio ) , Music player

เรารับผลิตสินค้า OEM Consumer

เรารับผลิตสินค้า OEM สำหรับกลุ่มผลิตภัณฑ์ Consumer อทิเช่น กระติกน้ำสูญญากาศ, เครื่องประดับ , เครื่องตรวจเช็คอัญมณี

CUSTOMER

ขอขอบคุณลูกค้า 30 ปี

ข่าวสารกิจกรรม

ข่าวสารกิจกรรม SUNARROW

SUNARROW CITI THAILAND

SUNARROW CITI THAILAND